O-Calc Pro contains many features designed to enhance the accuracy of a pole model. In some cases, accurately modeling all available parameters of a pole can indicate that a pole does not comply with pole loading code requirements so its allowable capacity utilization exceeds 100%. When a pole’s groundline capacity utilization exceeds 100%, the pole should be replaced with a stronger pole, remedied with appropriate guying or attachment removal, or the pole’s bending capacity increased using an Osmose ET-Truss™.

The ET-Truss is a steel capacity upgrading system that securely attaches to an in-service wood pole, without service interruption. It works in conjunction with sound wood poles to create a combined capacity greater than the original pole bending capacity.

Modeling the application of an ET-Truss™ is available as an optional plugin within O-Calc Pro, known as the Osmose® ET-Truss™ Selector Tool. This plugin allows a user to take a modeled overloaded pole and determine the appropriate ET-Truss size to alleviate pole’s overload condition.

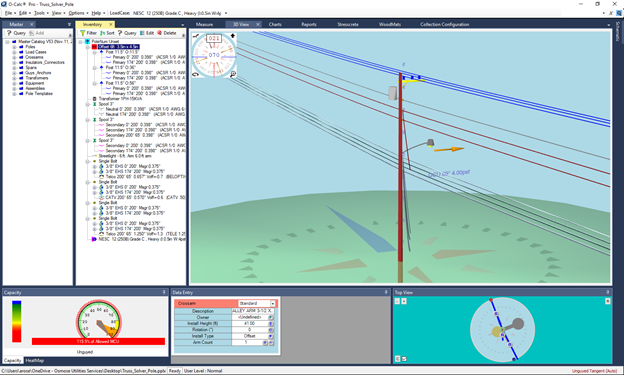

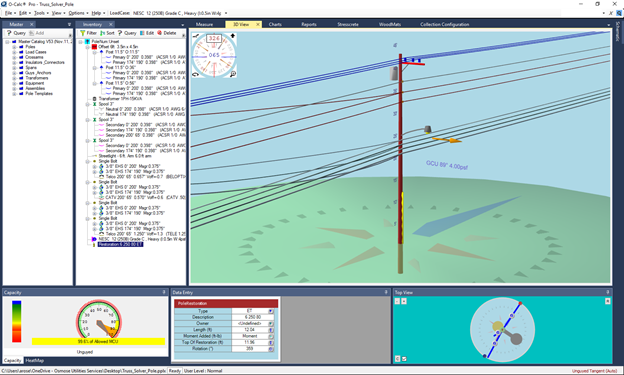

To demonstrate, below is a picture of a pole that is overloaded to code requirements.

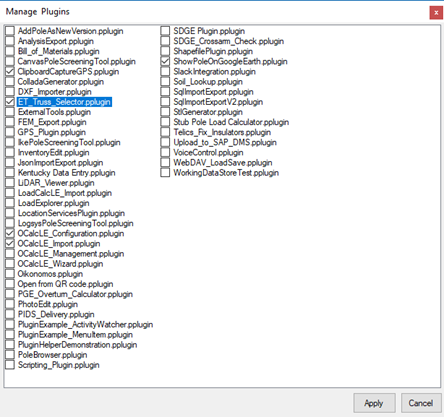

First, the user should make sure this plugin is enabled. This can be done by going to the Options drop-down list, and selecting Manage Plugins. In the menu, select the “ET_Truss_Selector.pplugin” option, and click Apply. This may restart your O-Calc Pro application.

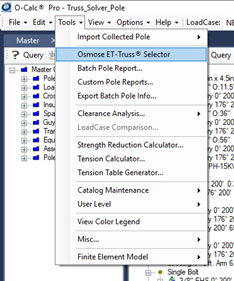

Once the program has restarted, the user can find the tool under the Tools drop down list, as shown here:

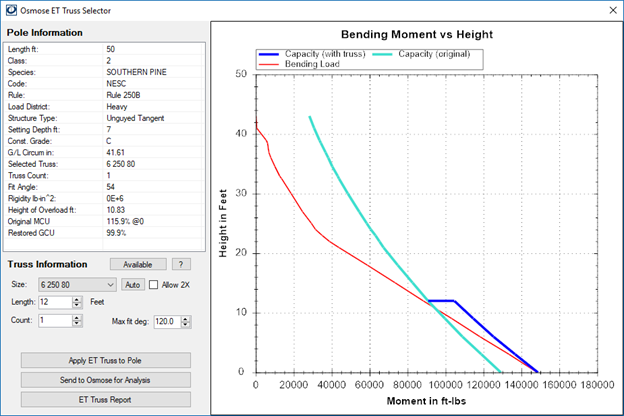

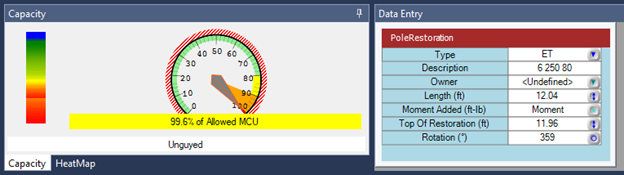

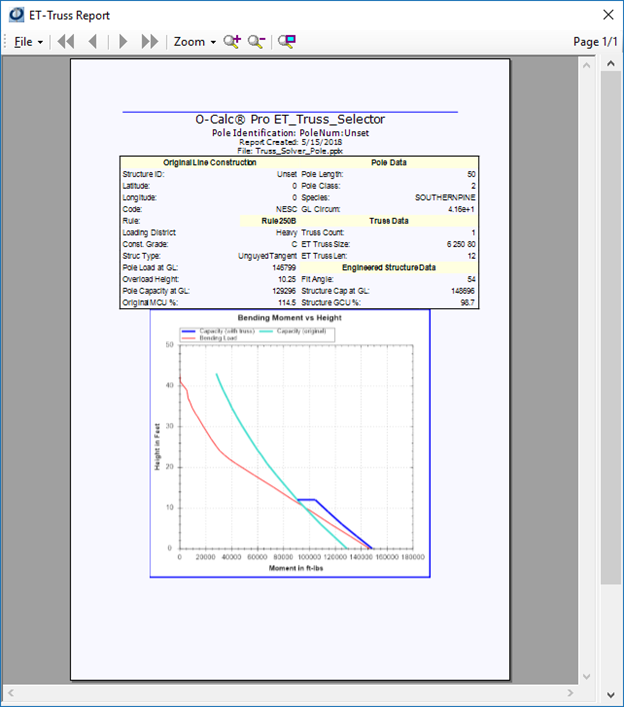

Selecting this option will open the tool for the pole that is being modeled. When the tool is opened, information will be populated related to the Pole’s Information, the Bending Moment v. Height information for this pole, and the selected Truss properties.

Here the pole information is shown in the upper left-hand corner of this window. The main pole attributes are shown, including the height, class, species, and the loadcase being applied. This information is used to draw the Bending Moment v. Height chart shown on the right-hand side of this window.

Within the Bending Moment v. Height Chart, the light blue line indicates the original capacity of the pole. The red line indicates the loading on the pole, which exceeds the light blue line where the pole is overloaded. The pole is considered overloaded in any section of the pole where the red line exceeds the light blue line. Overloaded poles are typically overloaded from groundline up to the point where the red and light blue line intersect. The dark blue line indicates the amount of capacity that would be restored by the currently selected truss.

The selected truss is shown in the bottom left-hand corner of this window. The selected truss is designated by the size drop-down list. This list contains all the available Osmose® ET-Truss™ sizes. When the tool is first opened, the smallest truss available to address the specific overload of the modeled pole is automatically selected. If the user would like to increase bending capacity of the structure beyond the minimum required, a different truss can be selected. By adjusting the selected truss in this list, the Bending Moment v. Height chart will change to reflect it.

Once the desired truss is selected, the user can submit the design to osmose by clicking the Send to Osmose For Analysis button. This will email the O-Calc Pro File to an Osmose representative who can assist in determining the appropriate ET-Truss solution for the pole in question.

Additionally, the Apply ET Truss to Pole button applies the selected truss to the pole model as a restoration object to correct the overload condition.

This image shows the truss (highlighted in yellow) included in the pole model – the truss is shown as “Restoration” in the inventory list.

The other option available is the ET Truss Report, which when selected, will open a window with the truss report formatted for printing or exporting.

For More information about the ET-Truss Selector Tool in O-Calc Pro or details about the ET-Truss solution, feel free to contact Osmose’s Pole Restoration Product Manager, Chad Newton at cnewton@osmose.com.

Recent Comments